Extensively supplied as original equipment and replacement spares on yaw and rotor brake systems, Trimat organic, semi metallic and sintered friction products provide proven durability and brake performance on the most demanding of on and offshore wind turbine applications.

Working closely with brake system manufacturers, Trimat have developed a range of friction materials specifically designed for wind turbine brakes that offer the following key characteristics, high strength, low wear rate, high friction and reduced brake noise.

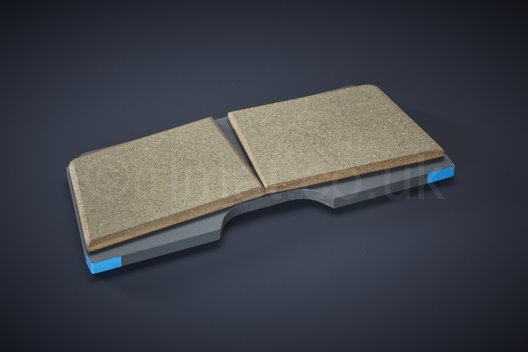

The materials can be supplied as finished brake parts integrally moulded or bonded onto steel backing plates, incorporating wear indicators if required. Alternatively they are available in standard sheet sizes for processing locally.

For further information on Trimat yaw brake products MN1056 and MN1130 or our rotor brake solutions MN1081 and SM, please contact us.