After years of experience working within both OEM and service replacement markets, Trimat recognise safety and efficiency are critical success factors for mining and excavation equipment. From our UK factory we produce a range of non-asbestos high performance friction materials for use on mine winders, conveyors, excavators, draglines and reclaimers.

All Trimat products have been developed with a focus on providing reliability, durability and control through key characteristics such as low wear, low noise and excellent fade resistance.

Woven products are CSIR approved and available with a brass or zinc wire inclusion and in non-metallic form, materials are produced in a wide range of sizes up to 32mm (1.25”) thick and 665mm (26”) wide. The products can be supplied as nominal 10m rolls, cut to length pieces, radiussed and machined to drawing complete with bonded keeper plates.

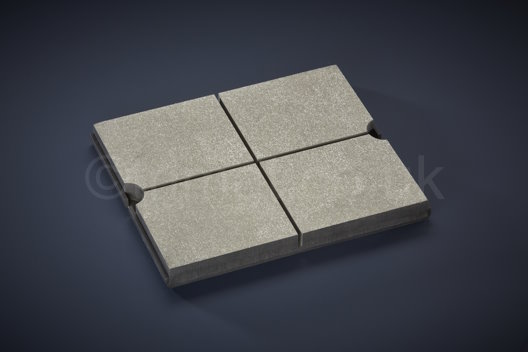

Press moulded disc brake pads are manufactured to customer drawing and supplied in an extensive range of organic, semi metallic and sintered materials to suit the demands of your individual application. All moulded qualities are also available in sheet form for local machining.

Trimat understand the importance of health and safety within the mining industry and manufacture a non-metallic material containing an active flame retardant which behaves as a spark, smoke and afterglow suppressant. These vital characteristics assist clients to comply with the latest ATEX regulations and improve safety standards for everyone.